When most of us think of insulation, we think of the kind of insulation that regulates temperatures, keeping buildings cooler in the summer, and warmer in the winter, preventing hazards from equipment or pipes overheating or freezing and preventing temperature leakage.

If you thought this, you’re not wrong. Insulation does usually refer to materials used to prevent the transfer of heat, especially in the context of buildings and certain types of equipment. In this traditional context, insulation is about maintaining temperature, conserving energy, and enhancing comfort.

However, the term “insulation” can also be applied in the electrical context.

There are, in fact, different types of insulation, for different purposes, one of those being electrical insulation, which prevents the flow of electrical current, for safety reasons.

When we discuss “insulation resistance”, we’re usually talking about insulation resistance in the world of electrical insulation. We’ll cover more on what this is, what it means practically, why it matters to business and industry, and how to test insulation resistance, within this article.

But first, let’s take a look at the different types of insulation, and cover off on electrical insulation.

The different types of insulation

Thermal insulation:

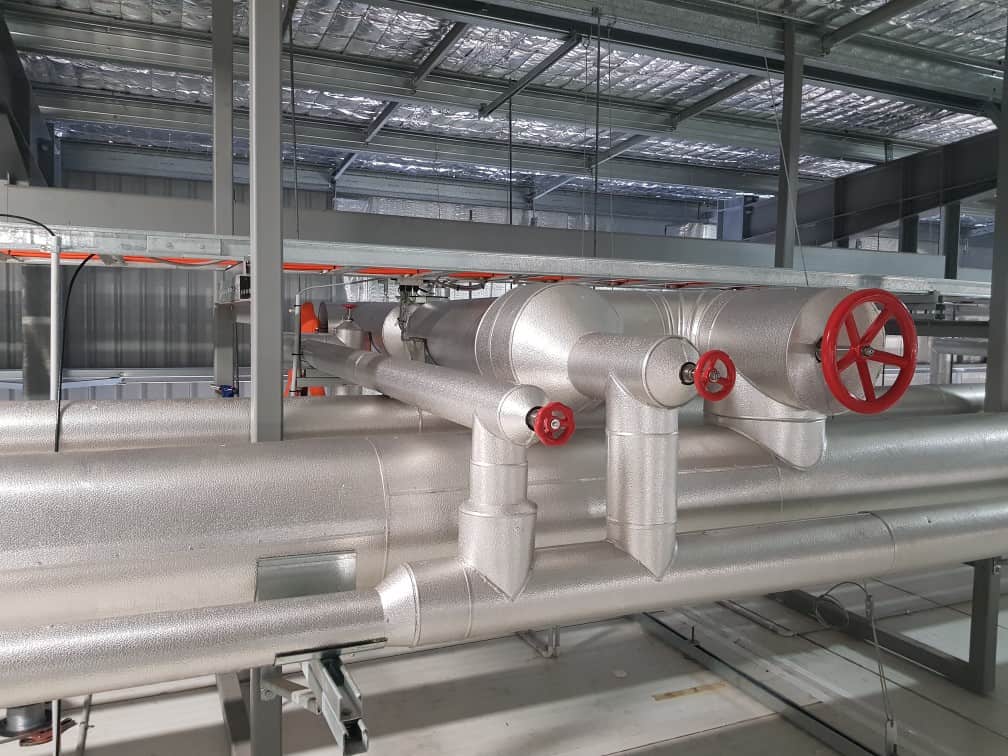

This type of insulation is focused on preventing heat transfer. It’s commonly used in buildings, HVAC systems, refrigeration units, and more. Its primary purpose is to maintain desired temperatures, conserve energy, and enhance comfort.

Electrical insulation:

This refers to materials that resist the flow of electrical current. Such insulations are used around wires, in commercial machinery, electrical devices, and electronic components. The primary goal is to prevent unintended electrical currents, which can lead to malfunctions, wear, and hazards like fires or electric shocks.

Acoustic insulation:

Acoustic insulation, also commonly referred to as soundproofing, is a technique used to control and reduce the transmission of sound between spaces. Its primary purpose is to prevent sound and loud noises from transferring from one part of the building to another.

Vibration insulation

Vibration insulation reduces the transfer of vibrations and is commonly used in industrial settings or in constructions near railroads or busy highways. Otherwise known as vibration isolation or vibration damping, vibration insulation minimises or prevents the transfer of vibrations in order to protect structures and equipment from vibrational damage, and reduces noise and wear.

What is Insulation Resistance, and Insulation Resistance Testing?

When we talk about “insulation resistance,” we usually are talking about electrical insulation resistance.

Again, electrical insulation is about preventing the unintended current flow of electrical current. It ensures that electrical currents remain confined within designated pathways, like wires or conductors, and don’t stray into areas where they could cause harm or malfunction.

So testing insulation resistance in the electrical insulation world, and measuring insulation resistance when it does occur, is crucial.

What is insulation resistance testing in electrical insulation?

The term ‘insulation resistance’ measures the resistance of insulating materials to the flow of electrical current.

When an insulation resistance test is conducted, it assesses how effectively an insulating material can prevent electrical leakage.

This is important for ensuring the safety and efficacy of electrical and electronic systems.

Can insulation resistance testing apply to other types of insulation?

The short answer is no. The term insulation resistance specifically relates to electrical insulation. However, the concept can apply to other types of insulation in terms of resistance to temperature flow, noise flow, and vibration flow.

So the concept of resistance in other forms of insulation does exist, but it’s described differently, using different words.

Here’s how it could apply in other areas.

Thermal resistance (R-Value):

In the context of thermal insulation, resistance to heat flow is described using the R-value. A higher R-value indicates better insulating effectiveness. This is commonly used to rate insulation materials for buildings, such as fibreglass, foam board, or cellulose. The R-value measures how well a material resists the conductive flow of heat.

Acoustic insulation:

While not labelled “resistance,” acoustic insulation effectiveness is usually measured in terms of Sound Transmission Class (STC) or Noise Reduction Coefficient (NRC). These values determine how well materials can prevent or absorb sound waves, respectively.

Vibration insulation:

Some materials are designed to dampen or resist vibrations, especially in industrial applications. While it’s not typically referred to as “resistance,” the effectiveness of such materials is assessed based on their ability to minimise vibration transfer.

This article focuses on the traditional sense of the term “insulation resistance testing”, meaning to measure the insulation resistance of electrical insulation.

Of course, if you need help with anything to do with insulation, whether it’s testing for thermal insulation, acoustic insulation, vibration insulation or electrical insulation, or anything else to do with insulation, our team is here to help. At Advanced Insulation & Fabrications, we know insulation.

Why is testing and measuring insulation resistance important for electrical insulation?

Accurate insulation resistance measurements are important for safety and operational efficiency.

Safety

Insulation resistance testing for electrical insulation is important for safety because they can identify problems and hazards that could cause injury such as electric shock, other electrical mishaps, potential fires, and other big issues. It’s important to test whether there is electrical leakage, how much the leakage currents are, and test voltage of the current flows for any leakage, in order to prevent hazards.

Operational efficiency

Insulation resistance testing is important to ensure that your electrical equipment performs at its peak.

How do you test and measure insulation resistance for electrical insulation?

If you’re wondering how to test insulation resistance, it’s important to mention that testing and measuring your insulation resistance is best done by a professional insulation resistance tester.

A trained professional will know how to do an insulation resistance test safely, and effectively, and get the correct insulation resistance measurement.

The equipment required for an insulation resistance test

The main device used by insulation resistance testers is called an Insulation Resistance Tester, IR tester, or Megohmmeter. This IR tester device produces a high DC voltage (commonly 500V, 1kV, or higher), to measure resistance in the megaohm range.

As this is a high DC or AC voltage, safety is highly important. This is why it’s important that the person completing the test is experienced in this area and is fully across the safety components of it. The tests themselves can pose a significant risk of electrical shock if done incorrectly, unsafely, or without the correct safety processes and equipment.

If you need the help of a professional insulation tester, get in touch with us at Advanced Insulation & Fabrications.

The steps an insulation resistance tester will take

Keeping in mind that it’s safest if a trained IR tester who is trained in the correct safety processes and test method for how to do an insulation resistance test properly, the steps to test and measure insulation resistance are :

- Safety First

- Ensure that the equipment or system to be tested is de-energised.

- Disconnect the equipment from any source of power.

- Ensure all capacitors are discharged.

- Alert nearby personnel that testing is in progress.

- Ensure that the correct safety gear is worn by the IR tester.

- Preparation

- Clean all insulating surfaces to remove any contaminants, as dirt and moisture can impact resistance measurements.

- Ensure that the insulation resistance tester/megohmmeter is in good working condition.

- Connection

- Connect one lead of the tester to the conductor or part being tested.

- Connect the other lead to the ground or the equipment’s casing.

- Performing the test

- Turn on the insulation resistance tester.

- Select the desired test voltage (e.g., 500V, 1kV). The appropriate voltage typically depends on the specifications of the equipment being tested.

- Initiate the test. The tester will apply the selected voltage across the insulation.

- Read the insulation resistance value displayed on the tester after a minute. This is commonly referred to as the “1-minute value” and is a standard duration for many tests.

- Interpreting the results and documenting the resistance value

- A high resistance value (usually in megaohms) indicates good insulation.

- A low resistance value suggests deteriorating insulation which may be due to moisture, dirt, ageing, or physical damage to the insulation.

- Compare the results to manufacturer’s specifications or historical data for the equipment.

- Record the test results, date, temperature, and humidity. These factors can influence insulation resistance.

- Regularly documenting results can help in trend analysis over time.

- Reconnecting the equipment

- After testing has been completed, any equipment can be safely reconnected and returned to its original state.

- Preparation

Advanced IR test methods (if required)

Sometimes an advanced IR test method is needed. In these cases, the following advanced methods may be used by IR testers.

Time-resistance method

This involves noting resistance values over a specific period, say 10 minutes, to analyse how resistance changes over time. A steadily increasing resistance often indicates good insulation, while erratic or decreasing values can signal issues.

Dielectric Absorption Ratio (DAR)

The DAR is the ratio of the insulation resistance at 1 minute to the resistance at 30 seconds. A value above 1.5 is typically considered good for most equipment.

What is a good result in insulation resistance for electrical insulation?

Insulation resistance defines how effectively insulating materials prevent the leakage of electrical current.

Effective insulation will consistently provide high insulation resistance, ensuring electrical safety and system efficiency.

When insulation deteriorates, the measured resistance drops, leading to potential risks.

High resistance value

A high resistance value is a positive sign, indicating the insulation is functioning effectively.

Low resistance value

A low resistance value signals potential issues, like moisture or contamination. This could mean the insulation deteriorates, or is insufficient, and requires immediate action.

Common factors that may be impacting your insulation resistance values

Moisture

Water or moisture can drastically decrease insulation resistance.

Temperature

Extreme temperatures can affect the resistance value.

Age

As insulation deteriorates over time, a decline in measured resistance becomes noticeable.

Leakage current

An increased leakage current hints at lower insulation resistance.

The team you can count on for everything to do with insulation

Whether it’s testing your current insulation, installing insulation that is going to stand up to testing, or replacing old insulation with high-performing insulation, the team at Advanced Insulation and Fabrications are your go-to solution.

Here’s what makes us the best in the business of insulation:

Comprehensive solutions

From pipe insulation & lagging, to passive fire protection, to pre-insulated pipework, polyurethane spray foam, insulation covers, and other insulation solutions for industrial and commercial applications, we offer a wide range of solutions.

Decades of experience and expertise

20 years in the industry equips us to deliver unparalleled service and advice in the world of insulation.

Nationwide reach:

Based in Brisbane, our expertise spans the country. We offer great value and experience to clients right across Australia.

End-to-end services:

We design, manufacture, and install, ensuring quality throughout. You can come to us for your complete insulation needs.

Get in touch with us today for a free quote, or give our team a call.