Corrosion is a natural occurrence that can significantly damage materials and cause them to deteriorate over time. This process can be particularly harmful to metals, leading to substantial structural issues and reduced longevity if left untreated.

To combat these corrosion problems, corrosion control comes into play. It is a technique that utilises established engineering principles and practices with the specific aim to reduce or entirely prevent problems related to corrosion.

The importance of corrosion control cannot be overstated. It protects and prolongs the life of materials, ensures safety, reduces costly replacements and repairs, and ultimately, contributes to the success and efficiency of your operations.

In this post, we will explore the intricacies of corrosion control, and how you can effectively integrate it within your business to ensure the longevity of your equipment.

The Damaging Effects of Corrosion

Corrosion presents a significant challenge to many companies across numerous industries, particularly for companies that use materials such as steel and aluminium.

At its core, corrosion is an electrochemical reaction between a metal and its surrounding environment, causing the metal to deteriorate gradually. Factors such as moisture, temperature, chemical exposure, and even the presence of certain bacteria can accelerate this process, leading to various forms of corrosion such as rusting, pitting, or galvanic corrosion.

The impacts of corrosion extend beyond mere surface degradation, however. As it progresses, corrosion can severely compromise the structural integrity of the material, rendering it weak and prone to failure. This deterioration can drastically reduce the material’s service lifespan, leading to frequent replacements and elevated costs. Moreover, for critical applications like infrastructure, vehicles, and machinery, corrosion can pose significant safety risks, making surveying and controlling how far it spreads a vital aspect of material management and maintenance.

Unravelling the Financial Impact of Corrosion

Corrosion, if left unchecked, can exert a substantial financial burden on businesses due to direct and indirect costs.

Direct costs, including continuous repairs and replacements, range from small components to major infrastructure. Without adequate corrosion control, businesses might find themselves locked in a resource-draining cycle of endless maintenance.

Indirect costs, while less obvious, can surpass direct costs in their financial impact. These costs manifest in various ways, from unexpected shutdowns causing lost productivity and revenue, to heightened maintenance needs and supply chain disruptions. Such unforeseen complications can impact business relationships and harm a company’s reputation.

Moreover, certain industries face the risk of legal ramifications from corrosion-related incidents, which can lead to serious financial and reputation damage.

Given these potential negative financial impacts, implementing corrosion control into your business is an imperative and strategic business decision. Through implementing comprehensive corrosion control strategies, businesses can not only reduce costs and increase operational efficiency, but can also extend the lifespan of their materials and equipment. Therefore, corrosion control is not simply a safety precaution, but a cornerstone of cost-effective business operations.

Understanding Safety Concerns Related to Corrosion

Corrosion introduces more than just material degradation; it also harbours significant safety risks. A clear example is the corrosion of pipelines. Over time, pipelines can weaken, leading to leaks or even catastrophic ruptures. These failures can cause operational disruptions, public endangerment, and environmental damage. The Pacific Islands pipeline disaster stands as a stark testament to these hazards, underlining the critical need for proactive corrosion prevention and vigilant monitoring.

To guard against these risks, the implementation of comprehensive corrosion control systems and regular inspections is paramount. Investment in effective corrosion monitoring and proactive prevention methods not only minimises safety hazards, but also protects the environment and ensures the welfare of your employees working in close proximity to these operations. Thus, effective corrosion control represents a dual investment in the durability of infrastructure, and the safety of both operations and the wider community.

Proactively tackling corrosion issues allows businesses to sidestep costly repairs, avert potential lawsuits, and circumvent the indirect costs that accompany shutdowns and delays. Furthermore, by preventing leaks and ruptures through corrosion control measures, you protect the environment and reduce the risk of explosion or fire. Consequently, prioritising corrosion control emerges not merely as a safety strategy, but also as a prudent financial plan, one that delivers long-term benefits for businesses and their stakeholders.

Corrosion in Different Industries

Corrosion issues impact a plethora of industries, from construction and manufacturing to the maritime sector.

Each industry has its unique set of challenges. For example, storage tanks utilised in the oil and gas industry are frequently subject to corrosive substances, leading to potential leaks or even catastrophic failures. Similarly, maritime structures, such as ships, offshore platforms, and port facilities, face a relentless onslaught of salty seawater, which is known to be one of the most corrosive natural environments. This exposure to the elements accelerates a vessel’s rate of corrosion and deteriorates structures much faster than other corrosion methods.

The good news, however, is that these risks can be effectively managed with a well-strategized corrosion prevention plan. By integrating methods like protective coatings, cathodic protection, the use of corrosion inhibitors, and a selection of corrosion-resistant materials, industries can significantly mitigate corrosion’s damaging effects. It’s not just about employing these strategies but tailoring them to the specific needs of each industry, taking into consideration the operational environment and material characteristics. Through such tailored corrosion prevention strategies, businesses can extend their equipment’s lifespan, increase safety, and, ultimately, boost their bottom line.

What are the types of corrosion control?

Controlling corrosion requires a comprehensive approach that utilises various effective methods, each possessing its unique strengths. The choice of the most suitable method depends on the project’s specific demands, including the type of material, the environment, and the application. Some methods include:

- Protective Coatings: These coatings form a barrier between the material and its environment, shielding the material from corrosive agents. They are often made of polymers, paint, or metals, and their effectiveness varies based on the coating material and specific conditions.

- Cathodic Protection: This method involves applying a direct current to counteract the electrochemical process of corrosion. Particularly useful for large structures, it prevents the material from oxidising and subsequently corroding.

- Corrosion Inhibitors: Corrosion inhibitors are chemicals that reduce the corrosion rate when added to a liquid or gas. They work in various ways, such as forming a protective film on the material's surface or altering the properties of the corrosive agent.

- Material Selection: This approach involves selecting materials known for their corrosion-resistant properties, such as stainless steel or aluminium alloys. Despite potentially higher upfront costs, this method can lead to significant long-term savings by minimising maintenance and replacement needs.

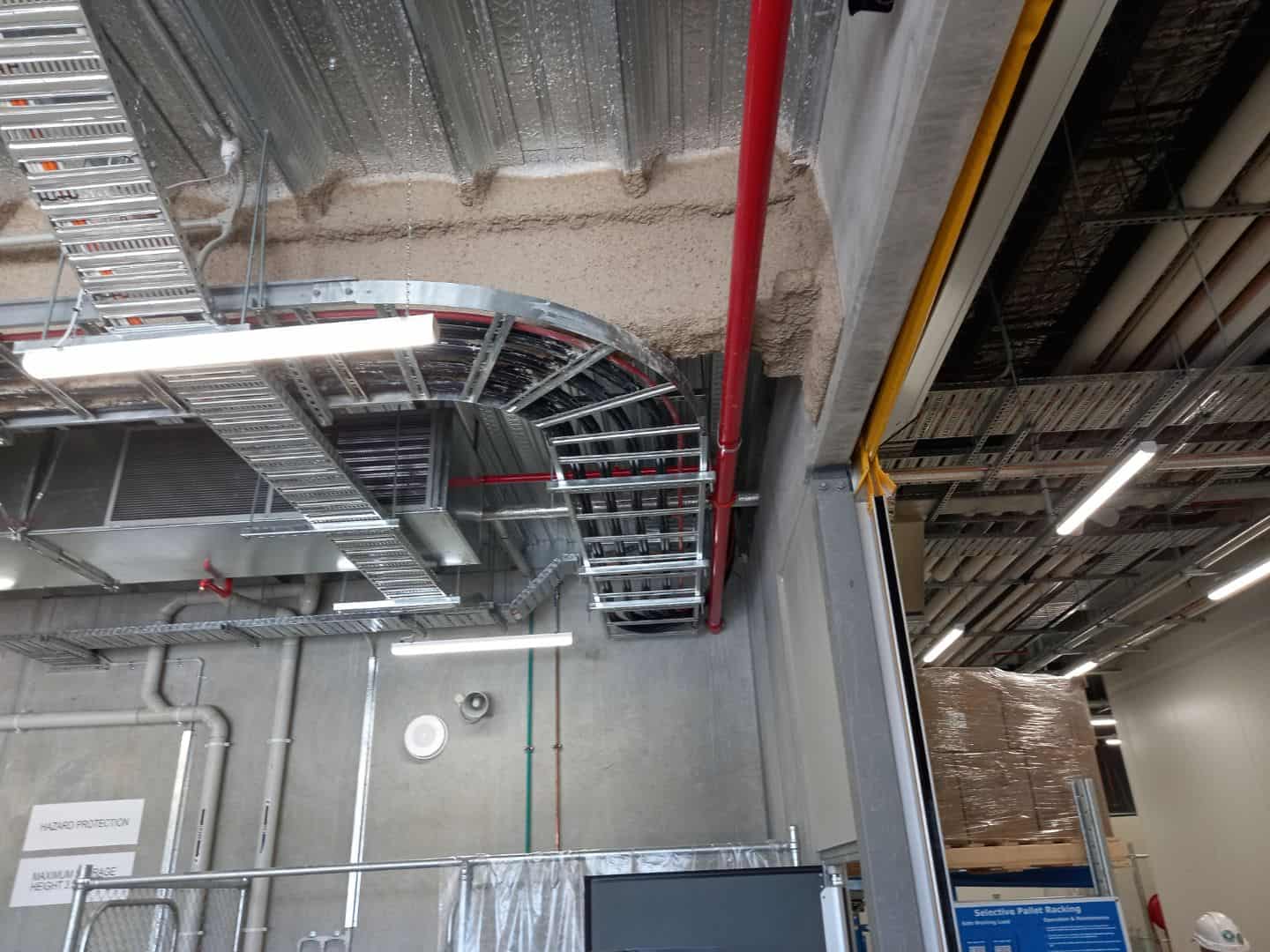

The Role of Insulation in Corrosion Control

Insulation plays a crucial role in mitigating the risk of corrosion, particularly in cases of ‘corrosion under insulation’ (CUI). CUI is a severe form of corrosion that occurs when water or moisture gets trapped beneath the insulation layer of a structure. This trapped moisture creates an ideal environment for corrosion, leading to accelerated material degradation that often goes unnoticed due to the covering insulation.

A robust insulation installation can significantly reduce this risk. By using appropriate insulation materials and techniques, the potential for condensation and subsequent corrosion beneath the insulation can be effectively minimised. Good quality insulation acts as a barrier against environmental factors like humidity and temperature fluctuations, preventing the formation of condensation. Furthermore, the use of moisture-resistant or hydrophobic insulation materials can further enhance this protection, safeguarding the underlying structures from the detrimental effects of corrosion.

Don't wait. Implement anti-corrosion measures on your assets today.

Effectively controlling corrosion is more than just a safety precaution; it’s a strategic business decision that can significantly reduce operational costs, enhance safety measures, and extend the service lifespan of your materials and equipment. By mitigating the damaging effects of corrosion, your business not only ensures a resilient model, but also encourages sustainable practices through reduced waste from premature equipment replacements.

Professionally installed corrosion insulation is not only a safety measure but also a smart, cost-saving move for your business. At Advanced Insulation & Fabrications, we’re passionate about empowering your business with expert corrosion control solutions. With over 20 years of experience servicing companies across Brisbane, we offer a range of industrial and commercial insulation services, including the creation of pre-insulated pipework, spray foam, and insulation covers, along with passive fire protection.

Take a proactive approach towards corrosion control and trust us to provide you with expert guidance and tailored solutions to keep your business safe, efficient, and cost-effective. Contact us today for a free quote and invest in a corrosion-free future for your business.